Plasma actuators represent a breakthrough in aerodynamic flow control, using ionized gas to manipulate airflow without moving parts.

Real-World Applications

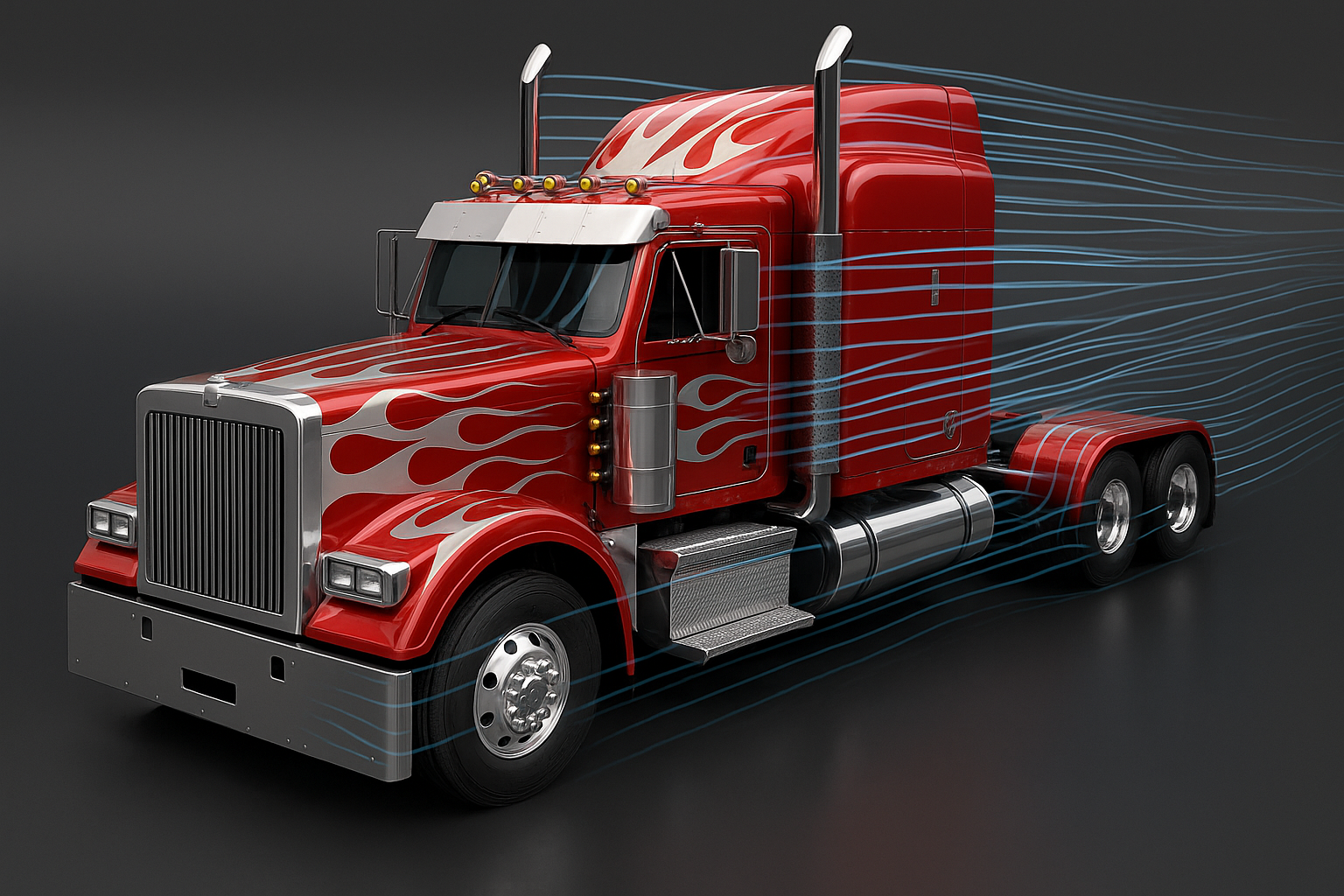

Commercial Vehicle Efficiency

Our plasma actuator technology demonstrates remarkable effectiveness in commercial vehicle applications, offering substantial improvements in fuel efficiency and operational costs.

- ✓ Significant fuel savings: £2,500+ per vehicle annually

- ✓ Reduced CO₂ emissions: 6 tonnes CO₂ saved per vehicle

- ✓ Enhanced aerodynamic performance at highway speeds

- ✓ Solid-state technology with minimal maintenance

Data Center Cooling Revolution

Data centers battle soaring heat densities, airflow bottlenecks, and localized hotspots, which drive noisy, failure-prone fan walls or complex liquid loops. Cooling typically consumes 10-40% of facility power, and in older sites it can approach the IT load itself.

- ✓ Targeted cooling: Ionic wind reduces hotspots and boosts heat transfer

- ✓ Silent operation: No vibration, ultra-flat for tight spaces

- ✓ Higher reliability: No bearings or blades, fewer mechanical failures

- ✓ Fine control: Fast voltage modulation enables closed-loop thermal control

- ✓ System efficiency: Orders of magnitude lower power vs traditional cooling

Aircraft De-icing Systems

Aircraft and UAVs operating in Arctic and high-altitude conditions suffer ice accretion that degrades lift, increases drag, and threatens mission success. Legacy de-icing systems are heavy, power-hungry, and maintenance-intensive, requiring innovative solutions for real-time ice prevention and removal.

- ✓ Multifunction design: Anti-icing, de-icing, and flow control in one system

- ✓ Efficient operation: >3°C/s heating with 70-90% lower power consumption

- ✓ Rugged design: Operates to -60°C with flush-mounted, conformal integration

- ✓ Real-time capability: Rapidly clears ice and prevents re-accumulation

- ✓ Aerodynamic enhancement: Improved lift, reduced drag, and stall delay

Innovating the Future of Aerospace

Our plasma actuator technology offers a revolutionary approach to active flow control, enabling more efficient and responsive aircraft designs.